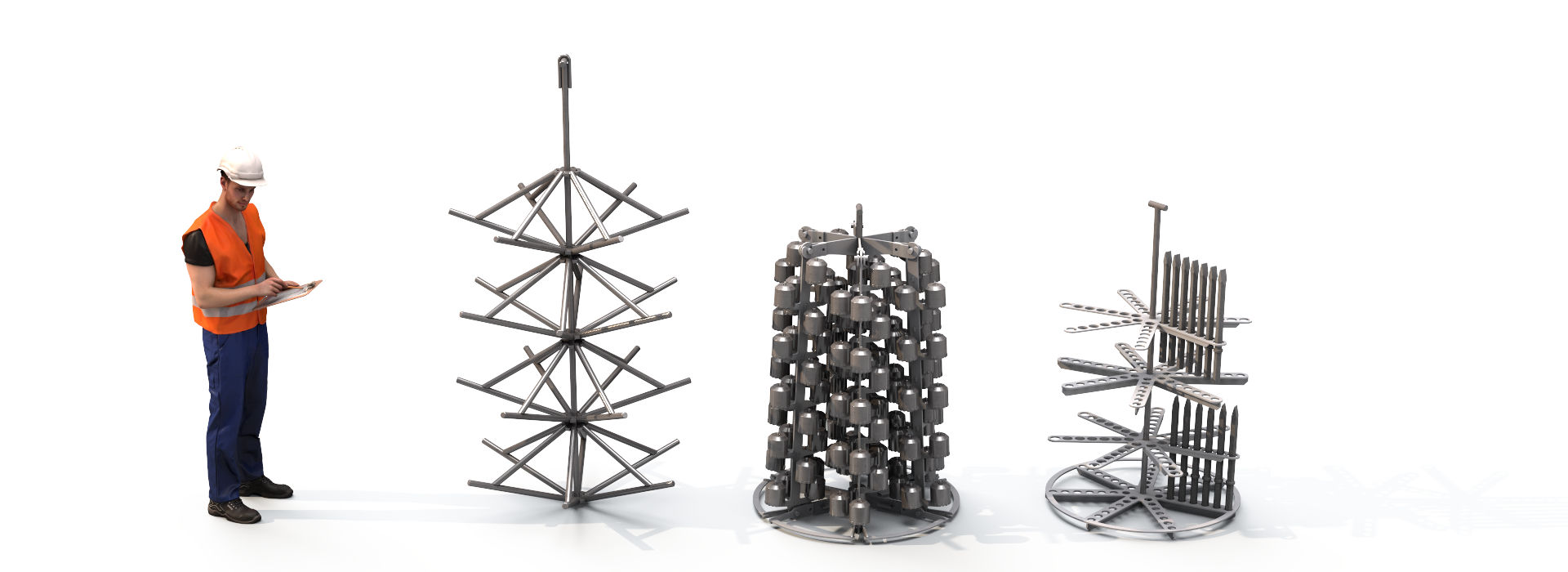

Equipment for sandblasters

Sandblasters are those machines that are used to clean darkened pieces after being heat treated and hardened in oil, thanks to the mechanical action of steel balls that strike and rub the piece inside of the appropriate room.

Thanks to our many years of experience in the metallurgical sector and loading equipment for heat treatment, we have begun to design, develop and build equipment and spare parts for sandblasters, as well as for industrial furnaces, our core business.

Also in this case, our staff is able to design from scratch, or starting from the customer’s drawing, components for sandblasters that correspond to the needs of those who request them; the equipment and spare parts ensure the best possible performance and maximum duration, in order to amortize the cost over the years and be a product with an excellent quality-price ratio.

The components for the sandblasters, in fact, are made only and exclusively with steels with a high manganese content in order to resist the powerful corrosive action of the cleaning procedure of the pieces: this material is not easy to build , but it is absolutely the most suitable to guarantee the best performance and a long life for any equipment or spare part, clearly superior to those produced in simple cemented carbon steel. A component for sandblasters made of cemented steel, in fact, has a life of only a few months, while that of a component made of manganese steel reaches more than ten years.

Showing the single result